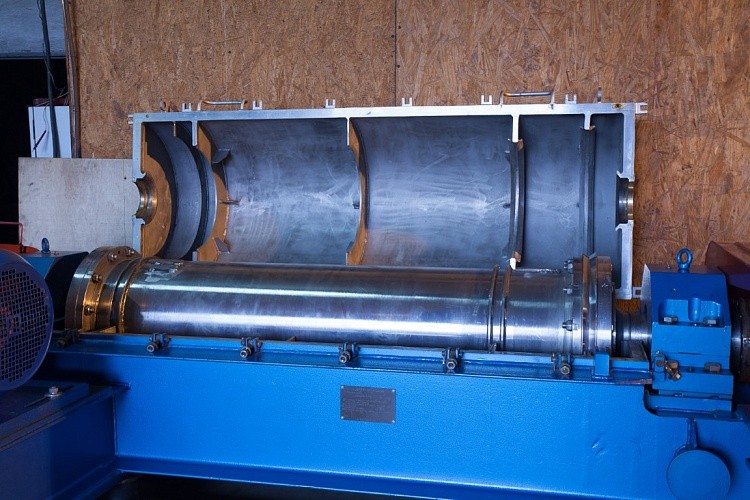

Decanter centrifuges

A typical industrial centrifuge is a rotating cylindrical and conic drum with coaxially rotating screws for the deposit of solid particles. During rotation of the drum centrifugal force separates solid particles from the sludge mass. The centrifugal force is greater than the gravity because of high speed of rotation. Particles remain on drum walls in the form of a dehydrated layer. Centrifugal acceleration during rotation is as high as 3000 g (versus 1 g in case of natural gravitation) and the separation of all phases of the rotated mass occurs faster and more effectively.

Advantages of the TehDag centrifuge

- The TehDeg C1-305 centrifuge with a rotor with the diameter of 305 mm successfully processes up to 20 m3 of liquid sediments an hour with a humidity of up to 96% from any sewerage treatment systems.

- The “C” series centrifuges (two-phase and three-phase) are delivered in a single design version for customers of any industries and descriptions of the product to be processed. This is their standardisation feature.

- Operational costs are minimal. The electric motors used are of low power, the consumption of flocculant is reduced. For example, the C1-305 centrifuge with a capacity up to 20 m3 an hour has an engine with a power of just 18.5 kW and the turning engine of 3 kW. The C2-455 centrifuge takes productivity to 50 m3 an hour, and the main engine is rated just for 37 kW, the turning engine — for 5.5 kW.

- Simplicity and speed of service.

- Reasonable price. It is lower by 30% than the purchasing price with foreign producers, with more advantageous characteristics by weight, dimensions, and output capacity. Actual technological capacity brings the cost of “C” series centrifuges to a half the price of a foreign alternative.

All three-phase suspensions (solid fraction + two liquids) with discharge of sludge cake and separate drain of two different liquids are treated by three-phase centrifuges (tricanters).

and we will prepare a commercial offer for you Request a questionnaire